The Glorious journey of “The Capital King” began in year of 2008 with consultation to the manufacturers of Conveyor Belt, Rubber Sheet, & Rubber Rollers, helping them in design, manufacturing process, quality improvement, production process control and developing compounds/formulation for the several applications and products

“The Capital King” has a backing of a strong and dedicated team with experience of over 35 years from the every rubber and engineering industry like Tires, Belting, and Rubber Sheeting OEM’s

We have a team which has decades of experience in field of manufacturing, research and development, innovation, implementation of new technologies, to name a few. We are not mere a company, “WE ARE THE TREND SETTER”

After Gaining consultation exposure and deep knowledge of market demand and expectation in the International and National Market for the Rubber industries, and going a notch higher The Capital King started to manufacture & supply of the expertise Rubber products Viz., Rubber Sheeting & Conveyor Belting

Capital king conveyor belts a smooth surface are useful for conveying of packed and unpacked material up to the angle of inclination 22° as an upper limit. Capital King has developed a wide variety of CONVEYOR BELTS.

Our Belts have found satisfactory customers in the Domestic and the International export market with our clientele ranging.

Width upto 2400mm

Length upto 400 Mtrs. Max. Dia 10 Feet

.range_box Open or Endless

Edges Cut or Moulded / Protected

Fabric Piles 2 to 10 in Polyester/Nylon (EP) Nylon/Nylon (NH), Coton/Nylon (CN) or Cotton/Cotton (CC)

Carcass Construction Straight PlyStepped Ply Reverse Stepped Ply.

Cover Thickness As per Customer Specification

Capital king developed excellent resilience, endurance and dimensional stability, makes it the obvious choice for all your flooring needs. These floorings are available in different colors, designs, thicknesses and grades to fulfill the requirements of our clients. With R&D facilities continually refining its manufacturing process you are assured of a high quality product that will serve you for years to come. Easy to install, our rubber floorings can be easily clean & maintain and assure longer functional life.

Belt Conveyor Systems have been recognized as one of the most reliable and cost effective ways to transport bulk materials from one point to another. However a poorly designed and maintained conveyor system can quickly erode those savings, with excessive spillage which consequentially leads to a number of perils within the conveyor system resulting in lower efficiency as well as monetary losses.

At Capital King , our history of relevant experience and technical competence provides a systematic approach to improve the efficiency of your operations by reducing both direct & indirect operational costs and further solving complex material spillage issues. Our trained team can recognize the visible as well as non-visible factors that cause the material spillage and then provide the solutions & superior engineering products through our program.

Lagging is the term used to describe the application of a coating, cover or wearing surface which is sometimes applied to pulley shells....

Conveyor Idlers are the heart of a conveyor, since reliability and longer life can reduce down time for the conveyors, effect reduction in ...

We are pleased to introduce non metallic , polymer conveyor rollers suitable for corrosive and adverse applications....

Our frames can be fitted in several ways in various kinds of conveyor structures. We fabricated each & every Frame...

widely in the bulk handling industry, from quarrying to mining, impact bars are an integral part of Conveyor Belt Support and Spillage...

We have developed a range of anti abrasive Rubber Sheeting specifically suited for the mining industry. Natural rubber is an outstanding abrasion , impact and corrosion resistant material. The inherent properties of strength, resilience and cut resistance have a direct effect on wear performance.

Widely used in shot blasting industry, rubber lining for material handling equipment or any other crucial application to reduce wear and tear of the parts / equipment s , screen decks and heavy duty transfer cutes where cutting & slashing by sharp edge heavy particles is the leading cause of abrasion.

We make also rubber sheets with neoprene backing which creates betters adhesion property in various usages. Our products has excellent specific gravity, tensile & elongation properties. This provides unmatched wear performance in the toughest abrasion environments.

Our extensive R & D facilities are available to investigate new products and materials, to serve the needs of our customers with better approach.

Lagging is the term used to describe the application of a coating, cover or wearing surface which is sometimes applied to pulley shells. Lagging is often applied in order to extant the life of the shell by providing a replaceable surface or to improve the friction between the belt and the pulley. notably drive pulleys..

Pulley lagging rubber sheets are used to eliminate belt slippage, increase pulley life, improve water shedding and boost productivity.

Pulley lagging rubber sheet

Gutter less design for cleaner compatibility reduces belt vibration and cleaner chatter for standard applications with minimal slippage.

8 mm to 40 mm

10000 mm

1000 mm ,1200 mm, 1400mm , 1500 mm

Black

Small

Medium

Large diamond

Square grooved

This is the standard pattern on all SpecDrum lagged conveyor pulleys. It is primarily used for reversing conveyor drive pulleys. It is also often used to allow bi-directional pulley rotation, and the pattern allows water to be dispersed away from the belt....

This style of finish is suitable for any pulley in the conveyor system where watershed is not necessary. It provides additional protection against belt wear, therefore, increasing the life of the pulley...

Diamond Grooved Rubber Sheet protects from wear and corrosion and reduces...

![]()

We have highly experienced technical team with world Class tools of belt jointing; We are specialist in, Belts Jointing and Repairing of Textile and Steel Cord Belts through Hot and Cold vulcanization Process.

We do provide our splicing & maintenance services for the following belts

Splicing Method : Hot & Cold Vulcanisation

Conveyor Belt Repair & Maintenance Services

“We at “The Capital King” believe in explore and sharing our expertise by providing turnkey project to set-up full flash units in technical collaboration. We always welcome the company who keen and expand themselves into field of manufacturing to serve companies locally.

Our turnkey projects available for:

Project : Rubber Roller Re-covering unit

Industries: Offset Printing, Packaging, Lamination, News Paper, Tin work, Tissues & Towels, Film & Foils, Glass, Tannery, Rexene, Leather, Steel, Paper, Plywood, Textile etc

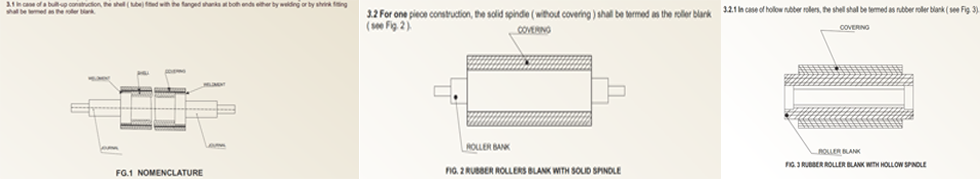

Rubber roller is "a rubber or an elastic material covering the core made of metal or other materials". Rubber rollers are used in wide application as above;

Industries as above has merely common uses of rubber rollers, Rubber Rollers plays a instrumental role in their manufacturing process. Cost of the rubber rollers for the industries who use its merely nothing in terms of their product cost.

Similar to other rubber & engineering products, Rubber Rollers also has wear & tear properties which making it unusable after duration of its rubber life.

What to do once rubber of rollers worn out? If someone use rubber worn out rollers in their machine that may possible that a small (re-covering) requirements makes a million of dollar machine useless and also cause entire rejection of produced material.

Benefits of project:

Project Profiles:

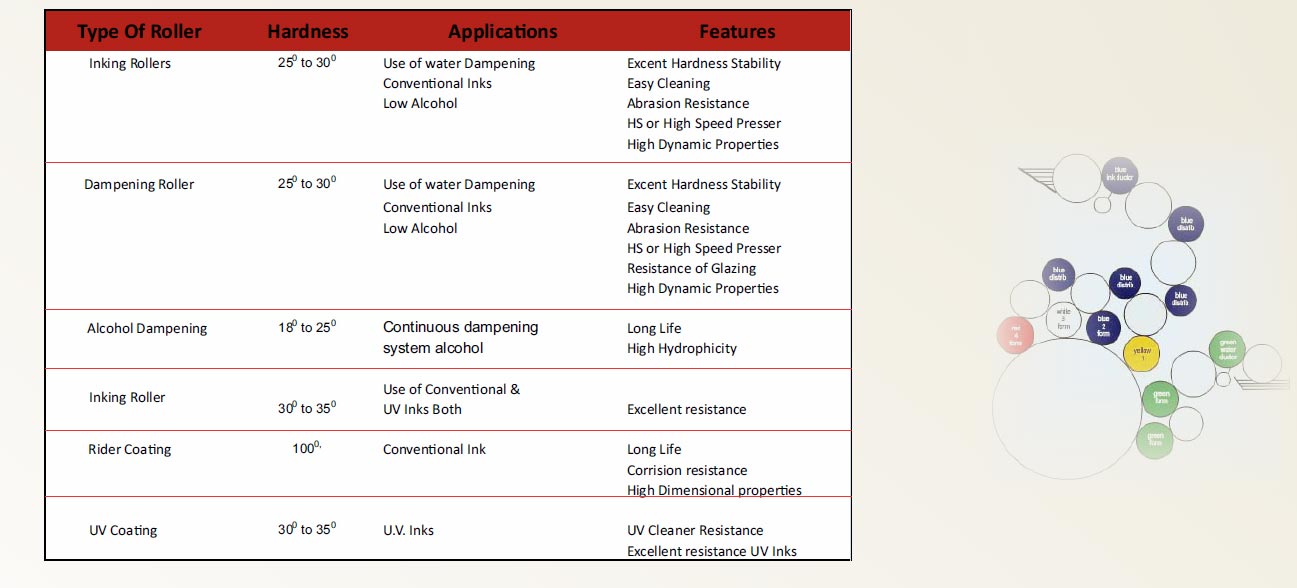

Used for Transferring ink and Water in Printing and Allied Industries such as Sheet Fed Offset, Web Offset, News Papers, Tin, Flexo & Roto Gravure Printing Machines & Lamination Machines

| Size of Rollers | Max. Length of Roller =1000mm |

| Max. Diameter of Roller =125mm | |

| Capacity | Upto 50 Rollers per shift |

| Operational Resource Requirement | |

| Floor Area | Min 300 Sq. Mts. |

| Total Power Reqd. | 80 H.P. /60 KW |

| Manpower (Minimum # s Specified) | |

| Technical Staff | 5 |

| Sales Personnel | 2-4 depending on Market |

| Administrative Staff | 3 |

Used for Transferring ink and Water in Printing and Allied Industries such as Sheet Fed Offset, Web Offset, News Papers, Tin, Flexo & Roto Gravure Printing Machines & Lamination Machines

| Size of Rollers | Max. Length of Roller = 3000mm |

| Max. Diameter of Roller = 500mm | |

| Capacity | Upto 100 Rollers per shift |

| Operational Resource Requirement | |

| Floor Area | Min 300 Sq. Mts. |

| Total Power Reqd. | 125 H.P. / 94 KW |

| Manpower (Minimum # s Specified) | |

| Technical Staff | 5 |

| Sales Personnel | 2-4 depending on Market |

| Administrative Staff | 3 |

Used for Transfering ink and Water in Printing and Allied Industries such as Sheet Fed Offset, Web Offset, News Papers, Tin, Flexo & Roto Gravure Printing Machines & Lamination Machines

| Size of Rollers | Max. Length of Roller = 3000mm |

| Max. Diameter of Roller = 500mm | |

| Capacity | Upto 200 Rollers per shift |

| Operational Resource Requirement | |

| Floor Area | Min 500 Sq. Mts. |

| Total Power Reqd. | min 220 H.P. / 165 KW |

| Manpower (Minimum # s Specified) | |

| Technical Staff | 8 |

| Sales Personnel | 2-4 depending on Market |

| Administrative Staff | 3 |

Used in textile Industry for Squeezing water, Dying, Coating and Wrapping the Fabric, in steel Industry for Rolling, Squeezing, Acid Removal and flattening the Steel Sheets, in Plywood industry for Glue Spreading, Straightening and Coating, in Tannery industry for Splitting, Setting & Buffing the Leather, in Packaging industry to Transfer ink and water, in Rexene Industry for Embossing, Spreading, Coating, Squeezing and in Thermal Power Plants, Mining, Glass, Chemical, Plastic, Food & Beverages Industries for Material Handling & Conveyors Similarly it has varied application in various other industries like Galvanizing Foam.

| Size of Rollers | Max. Length of Roller = 5000mm |

| Max. Diameter of Roller = 1000mm | |

| Operational Resource Requirement | |

| Floor Area | Min 700 Sq. Mts. |

| Manpower (Minimum # s Specified) | |

| Total Power Reqd. | 160 H.P. /120 KW |

| Technical Staff | 5 |

| Sales Personnel | 2-3 depending on Market |

| Administrative Staff | 3 |

In Paper & Board Mills for Squeezing, Drying, Wrapping and Spreading the paper pulp, in steel Industry for Rolling, Squeezing, Dying, Acid Removal and flattening the Steel Sheets, in Textile Industry for Squeezing water, Coating and Wrapping the Fabric in Plywood Industry for Glue Spreading, Straightening and Coating, in tannery Industry for Splitting, Setting & Buffing the Leather, in Packaging Industry to Transfer ink and water in Rexene Industry for Embossing, Spreading, Coating, Squeezing and in Thermal Power Plants, Glass and Plastic, Industries for Material Handling & Conveyors. Similarly it has varied application in various other industries like Galvanizing, Foam.

| Size of Rollers | Max. Length of Roller = 7000mm |

| Max. Diameter of Roller = 1600mm | |

| Operational Resource Requirement | |

| Floor Area | Min 2000 Sq. Mts. |

| Manpower (Minimum # s Specified) | |

| Total Power Reqd. | 365 H.P. / 274 KW |

| Technical Staff | 8 |

| Sales Personnel | 2-3 depending on Market |

| Administrative Staff | 3 |

The Capital King will supply all necessary machinery for setting up roller re-covering unit. These all machineries have been designed / development specifically for roller re-covering as per technical know-how of “The Capital King”

The Machines are specially designed for the above project

![]() All the Machines are fitted with Electrical Motors & Panels

All the Machines are fitted with Electrical Motors & Panels

![]() Tools, Measuring Instruments & Fixtures

Tools, Measuring Instruments & Fixtures

![]() Installation & Training

Installation & Training

![]() Sales and Marketing Support

Sales and Marketing Support

![]() One year warranty aganist any manufacturing defect

One year warranty aganist any manufacturing defect

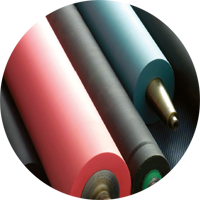

Capital King Produced high-quality Rubber Rollers, (New & Re-Refurbished of old Rubber Rollers) for machinery used in the Paper Industry, Textile Industry, Steel Industry, Plywood Industry, Tannery industry, Packaging industry and Printing industry. After a long period of research and market assessment, We are one of the most esteemed names in the manufacturing and supplying industry of a superlative array Rubber Rollers. These rolls are designed in accordance with the industrial standards. We do not make compromise in terms of quality and make use of premium quality rubber for carrying out the manufacturing processes of these rolls. These rolls are available in different grades and dimensions as per the requirement of the clients.

Types of Rollers

4, Material

4.1 Spindle

4.1.1 Solid spindles shall be made from mild steel conforming to IS : 226-1975 ‘Specification for structural steel ( standard quality) (first revision )’ or Grade 1 of IS : 7283-1974 Specification for hot rolled bars for production of bright bars‘.

4.1.2 Hollow spindle shall be made from steel tubes conforming to IS : 3601-1966 ‘Specification for steel tubes for mechanical and general engineering purposes’.

4.2 Covering- For rubber rollers used as inking rollers, the material for covering shall be good quality nitrile ( acrylo-nitrile butadyne) rubber of shore A hardness as indicated in Table 1, with natural resistance to cleaning material, namely, kerosene or petrol as well as to solvents used in printing inks, in as much as the change in form, shape or hardness and no excessive wear lakes place when in regular contact with such media.

4.2.1 For rubber rollers for use as water rollers, the rubber used shall have high resistance to alcohol and water and shall be of shore hardness as indicated in Table 1.

( Clauses 4.2 and 4.2.1 )

| TABLE 1 HARDNESS FOR RUBBER ROLLERS | |

| TYPES | Shore A Hardness |

| Ink forme roller | 25 to 32 |

| Transfer rollers | 28 to 32 |

| Ink vibrator rollers | 28 to 32 |

| Damping forme rollers | 22 to 26 |

| Damping vibrator rollers | 22 t0 26 |

5. Dimensions

5.1 As for diameter and length of the blank, sizes shall be generally guided by the design parameters of the printing machine, with special attention to high strength in bending,

5.2 Built-up roller blanks shall have a minimum tube wall thickness of 4 mm.

5.3 Spindle surface shall be rough-turning finished in the form of a helix with a close pitch, 0.5 to 1 mm

to ensure a good holding of the outer covering.

5.4 Minimum thickness of covering shall be

7 - 1 mm up to 50 mm diameter of rubber rollers

+0

10 - 1 mm above 50 mm diameter of rubber rollers

+o

6. Tolerance

6.1 Dimensional tolerance shall be

on diameter : + 0.1 to + 0.6 mm

on length : f3mm

6.2 Concentricity - O-1 mm total indicator reading ( TIR ), checked at centre of the covering length and

at 2 ends of covering, with respect to the axis of the journals.

6.3 Taper - 0.05 mm over a length of 1000 mm with ~respect to axis of and journals.

7. Workmanship - For rollers operating at higher speed ( above 2 m/s peripheral speed) the roller

blanks shall preferably-be dynamically balanced prior to rubberizing.

8. Finish

8.1 Damping rollers shall be of fine-ground finish. grinding traces which are visible but not perceptable, Light grinding stone flicks,

light chatter marks or by touch, are permissible. Imperfections in the surface, that is, holes, ridges, swelling, turning marks, or embedded

foreign particles shall not be acceptable.

8.2 inking rollers shall have a good grinding finish followed by a polishing operation to give it a velvet like surface. It shall be free from

all imperfections and defects as mentioned in 8.1

9. Test

9.1

Shore hardness testing shall be done at three points on the periphery 120” apart at three positions - one at the centre of the covering

length and at two other points approximately 1110 of covering length from either end.

9.2 Since hardness can be affected by temperature variation, the same test temperature shall be used throughout any one test or series

of tests for comparison. Test temperature recommended is 27 f 2°C.

9.3 Rubber rollers shall not loose its form or get damaged at working temperature up to 60°C.

10. Treatment - All exposed metal faces of the core shall be given a suitable rust preventive coating.

11. Marking - Manufacturer’s name, part number, date of manufacture and roller diameter shall be

stamped in a convenient place on the periphery of shank.

11.1 iSI Certification Marking - Details available with the Indian Standards Institution.

12. Preservation and Packing

12.1 Rollers shall be individually cleaned and covered with opaque paper and packed in corrugated sheets before packing in wooden boxes,

with journals resting in special fittings to ensure against any damage to the covering as well as to any loss of geometrical accuracy,

These shall be stored either horizontally or vertically.

12.2 For better preservation, rollers shall be stored in the dark with a relative humidity of about 65 percent.

Our development and success is founded on technical expertise and an ongoing commitment to excellence in customer service. We work closely with our clients, taking care to understand their requirements and to implement the optimum solution.We have utilised our technical knowledge of rubber technology to provide a wide range of high quality rubber for discerning customers worldwide. Driven by customer demand, we are constantly seeking to expand and improve our range of products and services.Specialists in new and refurbished ready to run rubber rollers.

Special Conveyor Belting

![]() Ultra Super High Temperature Belt

Ultra Super High Temperature Belt

![]() Cross – Stabilized Fabric Belt

Cross – Stabilized Fabric Belt

![]() CFW Special Fabric Belt

CFW Special Fabric Belt

Special Rubber Sheeting

![]() Super High Abrasion Resistance Sheet

Super High Abrasion Resistance Sheet

![]() Portable Water Rubber Sheet

Portable Water Rubber Sheet

![]() Electrical Insulation Sheet

Electrical Insulation Sheet

We are here to answer any questions you may have about our Capital King experiences. Reach out to us and we'll respond as soon as we can.

Even if there is something you have always wanted to experience and can't find it on Capital King

let us know and we promise we'll do our best to find it for you and send you there.

Telephone

+ 91 11 64746484

Tel-fax

+91 11 45576484

Mobile

+91 9999073386

Address

The Capital King Roller Co.

Plot No. 237, Ground Floor, Pocket-15, Sector-24, Rohini

New Delhi - 110085 | India